Knitting is an attractive alternative to 3D printing, and the arrival of a new Stoll flat knitting machine will only add to the appeal. This month, the TextielLab launched an ambitious R&D programme focusing on innovations in fully fashioned knitting.

After producing the world’s first industrially woven aluminium samples on the computer-controlled Dornier 170 loom in October, the TextielLab has now launched a major knitting R&D programme. The aim is to raise the profile of knitting in the visual arts by pushing the boundaries of the technique. “Historically, weaving has been a bigger part of our DNA,” says R&D project leader Noortje van den Elzen. This is why weavers have tended to take the lead in pioneering experiments in the lab. But the past year has seen the knitting department catching up fast.

The work ‘Dark Enough to see the Stars’ by Ada M. Patterson is created on the knitting machine. Photo: Patty van den Elshout / Product developer Sarena Huizinga and designer Alydia Wever at the knitting machine. Photo: Patty van den Elshout.

S machine

Investment in people and technology has been a big part of this. For example, the lab now owns a fully digitally configurable circular knitting machine that can handle thicker yarn, which has enormously increased the possibilities of circular knitting. The machine is mainly used in the industry for making mattresses, but product developer Mathilde Vandenbussche and technical specialist Yani Chuang are extensively testing it for other uses. In the meantime, the circular and flat knitting experts have introduced each other to ‘their’ machines, to enable more cross-pollination between the techniques. In terms of flat knitting, the team is eagerly awaiting the arrival of the latest machine: the STOLL CMS 830 ki S knit&wear E7.2, or the S machine for short.

Protrusions

The new machine, which will be installed in the lab just before Christmas, is ideally suited for so-called fully fashioned knitting. This is where seamless 3D shapes are knitted on the machine, rather than created out of individual components, often eliminating the need for assembly. “Basically, everything you can 3D print, you can knit, but with the quality and refinement of textiles,” says Van den Elzen. “We think that’s an interesting starting point for makers, even if they have never knitted in their lives.” Another benefit of the S machine is that it can knit even more distinct shapes than the current flat knitting machines, with longer floats and larger protrusions.

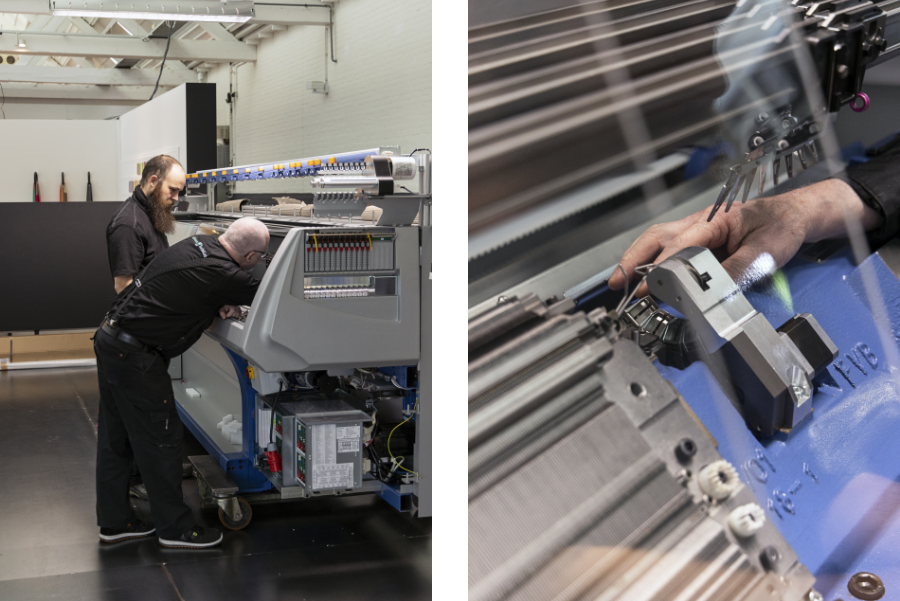

The s-machine is being installed in the lab. Photos: Josefina Eikenaar

Three artists

“We’ve noticed an increasing demand for fully fashioned knitting from makers,” says Van den Elzen, “but it’s also an area we want to grow in ourselves.” To this end, the lab has commissioned Elmo Mistiaen, Marlou Breuls and Henrik Vibskov for three R&D assignments. In 2024, they will explore the new possibilities of the S machine with the product developers, potentially in combination with the circular knitting machine. The idea is that the artists challenge both the product developers and the machines. The teams assembled for this purpose will each be given at least 40 development days in the lab, allowing them to delve into their research.

Voluminous body art

“The programme, which is supported by a government cultural subsidy, really makes time and space available for knitting,” says Van den Elzen. And it’s about much more than experimenting and producing interesting small-scale samples; an extensive 3D knitted object has to come out of it. “We want to make something spectacular.” The results will be shown in the TextielMuseum at the end of next year in an exhibition appropriately titled Volume – Transforming Identities. The first two artists have been commissioned to make a voluminous and sculptural body piece. The piece can, but doesn’t have to be, a wearable fashion item. However, it must add to the current discussion about body shaming, body positivity, sustainability and developments related to the manipulated body. First up is the Belgian artist Elmo Mistiaen, who uses artificial intelligence to design his ‘biomorphic outdoor fashion & weird design’.

“Everything you can 3D print, you can knit.”

Noortje van den Elzen

Sustainable samples

Mistiaen has been paired with product developer Sarena Huizinga for this project, and the two will start exploring the limits of the new machine this month. A key focus is the use of sustainable yarns, such as Dutch wool and post-consumer recycled yarn from the Tilburg-based company Wolkat. One of the goals of the R&D programme is to develop a series of sustainable samples and add them to the Sample Studio. “These examples give other designers a flying start, because the research has already been done and the technical specifications of the yarns are available,” explains Van den Elzen. “By making sustainable yarns visible and tangible in finished samples, it’s much more likely that other people will start working with them.”

Text: Willemijn de Jonge